Rewind and resolve – Automation Playback on OMRON's NX5 controller

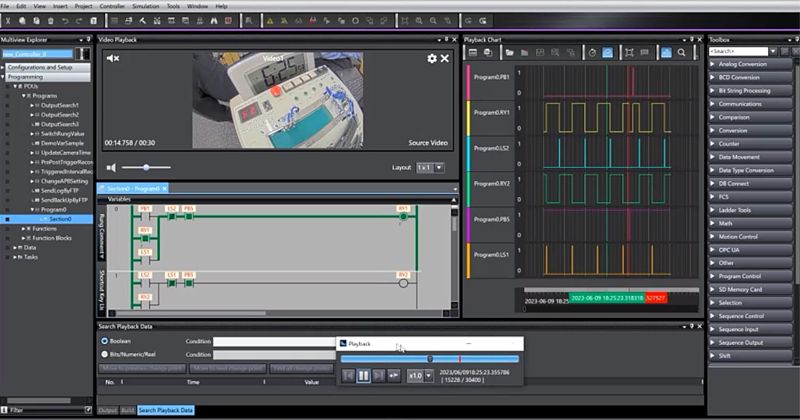

Ever wished you could rewind time when fixing a problem on your production line? In the world of manufacturing, OMRON has made that wish come true with Automation Playback, a standard but unique feature on its NX5 automation controller. Automation Playback is almost like the production line's very own "time machine".

Imagine this: you're on the manufacturing floor, a line stoppage occurs, and every second counts. With Automation Playback, there's no need to scramble. Like a "black box" for your production line, the NX5 controller records and stores real-time data, allowing you to pinpoint exactly when and where things went off course. You can even integrate external cameras for synchronized video material, making it a full-on detective of your production process, without slowing down performance.

Josep Martí, EMEA Product Marketing Manager for Modular Controllers, Servos and AI Control at OMRON clarifies: “Imagine, something that “never happened” happens. The machine stops working and no one knows why. Typically, to solve the problem, the technicians need to replace parts and troubleshoot until it is impossible to understand what happened anymore. This wastes valuable time and resources. With Automation Playback, you can see exactly what happened, backed by data and images.”

Automation Playback is designed with simplicity in mind. Implementation is straightforward—just select recorded information, choose the REC button, and set the recording time. It's as easy as that, allowing engineers to focus on problem-solving rather than complex setups.

Commissioning made simple

In today's fast-paced manufacturing industry, reducing commissioning time is critical, especially with the global shortage of skilled technical workers. Automation Playback captures thousands of control cycles per second, allowing teams to review and resolve issues before full production even begins. Setup errors? Gone. Downtime? Slashed. It’s like hitting "replay" until perfection is achieved.

A team effort – across the globe

With engineers often scattered across different countries, Automation Playback brings a new level of collaboration to the industry. Teams can analyze captured data from anywhere, sharing insights without even stepping onto the factory floor. By playing back the recorded data, like from a black box, team members can troubleshoot as if they were right there with the machine. This feature doesn’t just boost efficiency; it helps redefine how global teams work together, making distance irrelevant.

Efficiency in motion

In industries, such as EV manufacturing, where every minute of downtime means two fewer cars rolling off the line (and a potential loss of €100k), Automation Playback is a game-changer. OMRON’s NX5 controller can recall up to 15 minutes of data before and after a stoppage, enabling teams to fix problems in record time. This smart, seamless integration keeps production on track while safeguarding against future disruptions. In pharmaceutical production, the feature helps ensure product quality and compliance by quickly identifying and resolving production issues, minimizing downtime, and reducing the risk of costly product recalls.

So, is it a time machine? Maybe not exactly, but with OMRON’s NX5 Automation Playback, manufacturers can certainly rewind, review, and resolve—turning potential headaches into distant memories.

The NX5 with Automation Playback operates on OMRON's Sysmac integrated automation platform. This platform unifies control of various devices, including controllers, motion, vision, and safety systems, into a single architecture. It simplifies automation with real-time control and data processing.

News release from Omron, 02/09/2024

Feel free to share

Calendar

19/11 - 22/11: Formnext, Frankfurt am Main (D)

31/03/25 - 04/04/25: Hannover Messe, Hannover (D)

15/09/25 - 19/09/25: Schweissen & Schneiden, Messe Essen (D)

08/10/25 - 15/10/25: K, Düsseldorf (D)