Three breakthroughs in the history of the assembly line

Although it faces stiff competition from the steam engine and the PLC, the assembly line is generally regarded as the most important invention of all time in manufacturing technology. In this article, we take a look at three breakthroughs that have made their mark in the history of the assembly line.

The invention of the assembly line is credited to Ransom Eli Olds - the man who founded the Olds Motor Vehicle Company in Michigan in the late 1800s. Legend has it that Olds had a dozen prototypes ready when his factory burned down in 1901. Only one copy could be saved - the Curved Dash Oldsmobile - so it was decided to produce and market that model. A remarkable detail is that the prototypes had different drive technologies, namely steam, petrol and electric. At that time, the sector was more than ever at a tipping point, we shall conclude.

In 1901, the Olds Motor Vehicle Company produced 425 Curved Dash Oldsmobile. The following year, Ransom Eli Olds invented what would later be considered the first assembly line. It was a so-called static line where workers had to move the vehicles under construction themselves from one station to the next. The systematic approach meant that production could be increased to 2500 copies per year.

Six years later, the Olds Motor Vehicle Company became part of General Motors, which kept the Oldsmobile brand until 2004.

Conveyor with platforms

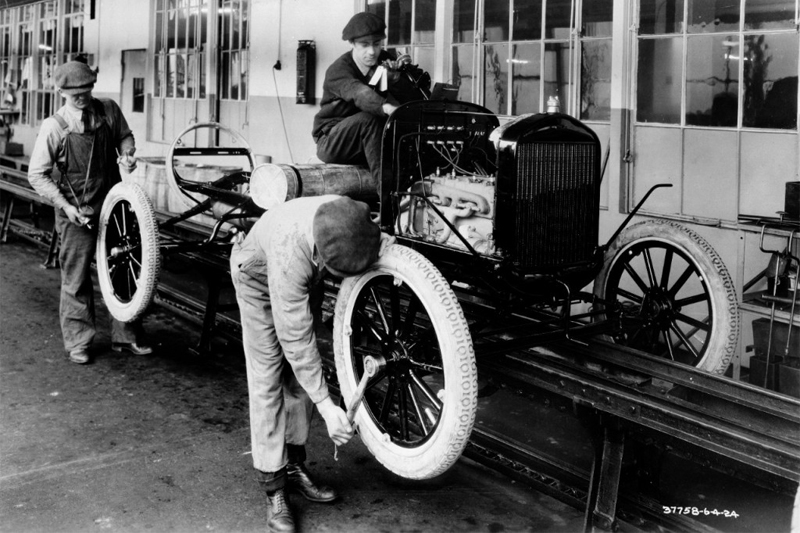

In 1908 - the year GM took ownership of the Oldsmobile brand - the Ford Motor Company started production of one of the absolute icons of the automotive industry - the Ford Model T. The Model T is considered the first car aimed at the mass market .

In those days, Henry Ford would have noted in newspapers that consumers could choose the color of their Model T themselves, as long as it was black. Limiting to a single color was one of a whole series of decisions, all aimed at producing the car as efficiently and therefore as cheaply as possible.

To make this possible, Ford also devised a conveyor with platforms on which the cars could be moved during assembly. These platforms were pulled with ropes on rails to guide the cars under construction without wasting time through the various production stations. In short, it was the first real assembly line. Every 90 minutes a new Model T rolled off the production line at the Ford factory.

Unimate - the first industrial robot

For the next big breakthrough, we have to go back to General Motors, which commissioned the first industrial robot on one of its assembly lines in 1961.

The Unimate was an invention of George Devol who called his machine a “Programmed Article Transfer Device”. When Devol spoke about his invention at a party with entrepreneur Joseph Engelberger, he is said to have replied that the machine reminded him very much of a robot. The term robot was coined by science fiction author Isaac Asimov. By making the link, Engelberger did not just come up with the name. His company also started looking for financing and a few years later - in 1961 - a first prototype was installed at General Motors.

The general public was first introduced to the robot in 1966 when it was demonstrated on the popular Tonight Show. In the show, the robot managed to hit a golf ball into a cup and pour out a pint of beer. By the way, Engelberger knew how to tackle it because that same year he signed a deal with Nokia to market the machine in Europe. In Japan, a license was granted to Kawasaki Heavy Industries.

General Motors used the Unimate for spot welding and created a production line with the robots capable of a capacity of 110 vehicles per hour - a capacity previously unimaginable. The Unimate is therefore, like the concept of the production line itself, considered one of the great breakthroughs in the history of the assembly line.

© Productivity.be, 25/10/2020, Picture: Ford

Feel free to share

Calendar

31/03/25 - 04/04/25: Hannover Messe, Hannover (D)

15/09/25 - 19/09/25: Schweissen & Schneiden, Messe Essen (D)

08/10/25 - 15/10/25: K, Düsseldorf (D)