Fraunhofer

USP laser structures and polishes hard material components in a single clamping operation

Fraunhofer - Tools made of hard materials and ceramics such as tungsten carbide are particularly wear-resistant. However, the tools used to manufacture them wear out all the faster – unless the tool is laser light. Researchers at Fraunhofer ILT have developed a process chain in which hard material components can be shaped and polished using an ultrashort pulse (USP) laser without changing the clamping setup.

Flexible beam-shaping platform optimizes LPBF processes

Fraunhofer - A new approach to beam shaping will soon make additive manufacturing more flexible and efficient: Fraunhofer ILT has developed a new platform that can be used to individually optimize laser powder bed fusion (LPBF) processes. Customized beam profiles improve component quality, reduce material losses and enable previously impossible scaling of the build-up rate of the single beam process.

Climate-Friendly Electricity Derived from Ammonia

Fraunhofer - Using hydrogen to generate electricity does not cause any climate-damaging emissions. But storing and transporting the gas pose technical challenges. With this in mind, Fraunhofer researchers use ammonia, a hydrogen derivative that is easier to handle, as a starting material. Ammonia is cracked in a high-temperature fuel cell stack, and the hydrogen produced in this process is converted to electricity. The waste heat can be used as heat energy, for example.

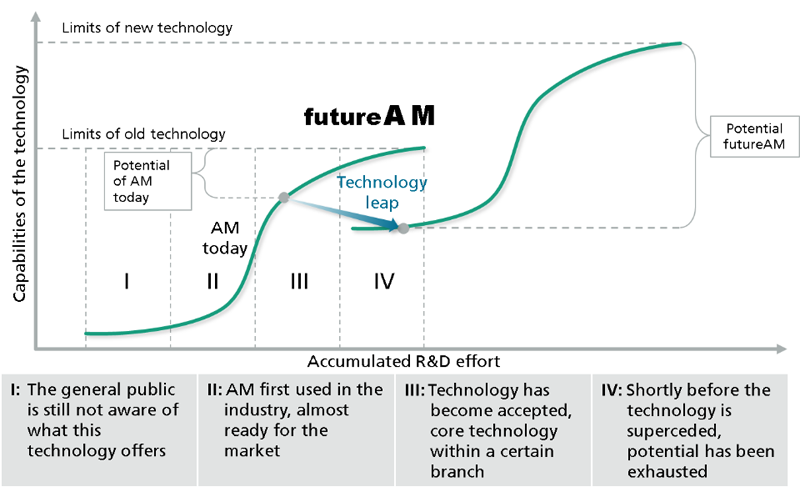

Additive Manufacturing in the throes of technological change

Fraunhofer - Additive Manufacturing, particularly metal 3D printing, has evolved from a promising technology to a serious constituent of industrial production. Industries such as plant engineering, aerospace, automotive and metalworking are facing a technological transformation that could have far-reaching implications for design, production and sustainability.

Easier and systematic qualification of AI applications

Fraunhofer - A new software framework is to make it easier for companies to approve or audit applications based on Artificial Intelligence (AI). The framework is being jointly developed by Fraunhofer IPA in conjunction with the Institute of Industrial Manufacturing and Management IFF at the University of Stuttgart as part of the “AIQualify” research project of the German Association for Quality (DGQ).

Recycling organic waste: biodegradable bags not currently recommended

Fraunhofer - Bags made from biodegradable materials for collecting organic household waste have been available on the market for several years. Now researchers in a large-scale pilot study have conducted an extensive investigation into whether these bags fully decompose. In addition, this — the first of its kind — study also took a look into the consumers interest in using biode-gradable bags.

Integrated Sensor Technology: The Next Step in Additive Manufacturing

Fraunhofer - The Fraunhofer Institute for Laser Technology ILT will be presenting the latest research results in additive manufacturing technology at the Fraunhofer joint stand at formnext in Frankfurt am Main from November 7 to 10, 2023. Among other things, the Aachen engineers will be showing additively manufactured sensors that are printed directly onto components and that can provide real-time data for predictive maintenance.

Recycling of refractory materials avoids 800,000 tons of CO₂

Fraunhofer - In the European research project ReSoURCE, experts from nine different companies and institutes are working together to develop sustainable solutions for the recycling of refractory materials. The German project partners are primarily providing laser know-how.

Heat-resistant ceramic ink for data codes on metal components

Fraunhofer - Fraunhofer researchers have developed an extremely heat-resistant ceramic-based ink. For the first time, this enables metal components processed in the automotive industry at temperatures over 1,000 ºC to be marked with a code. The code can be scanned and is linked to a database in which all the manufacturing parameters for the component in question are stored.

Powerful object recognition for diverse applications using AI and robotics

Fraunhofer - New algorithms for object recognition and environment perception have been developed at Fraunhofer IPA, enabling sophisticated automation solutions for the service and production sectors. They are a result of the “Knowledge4Retail” research project, in which twelve project partners have developed solutions for future-oriented retail.

Highly sensitive robot gripper

Fraunhofer - Force-sensitive, dynamic, energy efficient and with a range of applications – these qualities are what distinguish the new robot gripper created by the Fraunhofer Institute for Mechatronic Systems Design IEM. It can transport fragile objects from one production step to the next without damaging them. The gripper is specially designed for the food industry, where careful handling of fragile products helps to avoid waste. The electric drive makes costly pneumatics obsolete.

Greater Safety for Lone Workers

Fraunhofer - It is essential that people working alone are protected by systems that automatically detect threats such as fall hazards, potential medical emergencies or time spent in critical areas, and notify first responders or trigger warnings in appropriate areas. The systems that are currently in use are not capable of performing these tasks adequately. Wireless systems in particular have limitations in terms of real-time capability or range.

Energy harvesting: energy-autonomous IoT communication in 5G networks

Fraunhofer - Minimal vibrations, temperature differences and even light can be used to generate power for small electronic systems. At Booth B4/258 of the electronica 2022 trade show, Fraunhofer researchers will demonstrate how 5G radio modules with higher energy consumption can now be powered autonomously through energy harvesting — without the use of batteries and cables.

Simulation-based and highly dynamic: virtual prototyping

Fraunhofer - The things that amaze us in everyday life, such as when our cars take control of the parking process, are often the result of countless series of expensive and lengthy trials. At electronica, Booth B4/258, Fraunhofer researchers will demonstrate how virtual prototyping can be used for simulations to detect errors and problems in complex electronic control systems at an early stage as well as to shorten development times and significantly reduce costs.

Biointelligent sensor for measuring viral activity

Fraunhofer - Today, genome editing is almost as easy as programming software. However, the generation of viral vectors as initial material is still associated with many expensive and error-prone handling procedures. Viruses are generated via complex biological processes that have to be optimised virus-specifically in order to produce high-quality therapeutics. A new method is needed that simplifies and optimises these processes.

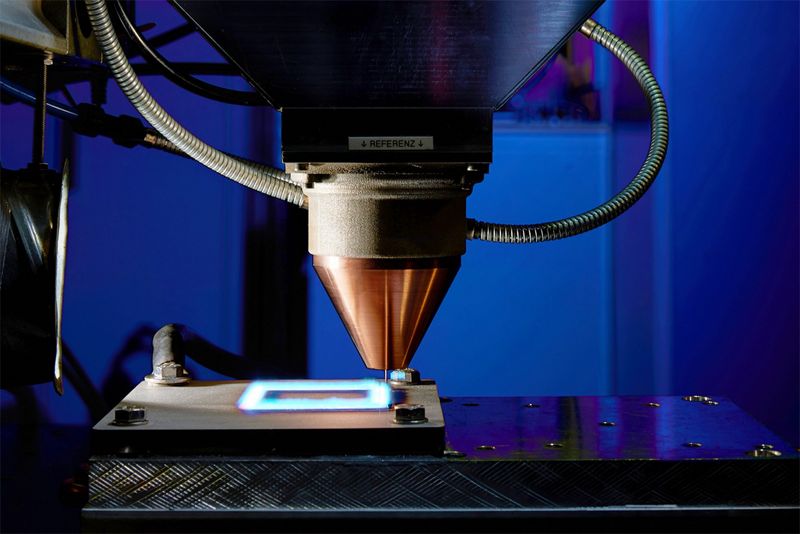

When a laser collar tames the arc

Fraunhofer - An example of hybrid technology in its purest form has been developed and built by the Fraunhofer Institute for Laser Technology ILT for the DVS research project “KoaxHybrid.” In Aachen, the institute engineers have developed a new optical system with glass substrates and an arc torch which unites metal shielding gas (MSG) welding and laser material deposition with an annular beam, thus creating a completely new process.

Laser-based sensor technology for recycling metals instead of mining mineral resources

Fraunhofer - In order to help the industry have greater access to raw materials, the Fraunhofer Institute for Laser Technology ILT and Cronimet Ferroleg. GmbH have jointly developed a laser-based sorting process for metal scrap as part of the BMBF-funded “PLUS” project. A new sensor they have developed makes the recycling of metallic raw materials many times more efficient than previously possible.

Fraunhofer Lighthouse Project futureAM Gets Metallic 3D Printing in Shape for Industrial Use

Fraunhofer - Accelerating the additive production of metal components by at least a factor of 10: With this goal in mind, the Fraunhofer-Gesellschaft launched the lighthouse project “futureAM – Next Generation Additive Manufacturing” in 2017. As the project ends in November 2020, six Fraunhofer institutes have made technological leaps forward in systems engineering, materials and process control as well as end-to-end digitalization.

IDAM: Network puts metallic 3D printing on track for automotive series production

Fraunhofer - On March 27, 2019, the joint project IDAM held its kick-off meeting in Munich, which was intended to pave the way for Additive Manufacturing to enter automotive series production. Specifically, the project partners – consisting of SMEs, large companies and research institutions – will transfer metallic 3D printing into an industrialized and highly automated series process in the automotive industry for the first time.

Calendar

25/11 - 27/11: SPS, Neurenberg (D)

04/02/26 - 06/02/26: Indumation.be, Kortrijk Xpo (B)

10/03/26 - 13/03/26: TechniShow, Jaarbeurs Utrecht

10/03/26 - 12/03/26: CFIA, Rennes

10/03/26 - 12/03/26: Embedded World, Nürnberg (D)

20/04/26 - 24/04/26: Hannover Messe, Hannover (D)

06/05/26 - 07/05/26: Advanced Engineering, Antwerp Expo (B)

06/05/26 - 07/05/26: Chemspec Europe, Keulen (D)

19/05/26 - 21/05/26: Advanced Manufacturing, Antwerp Expo (B)

20/05/26 - 21/05/26: Food Tech Event, Brabanthallen, 's-Hertogenbosch (Nl)

15/09/26 - 19/09/26: AMB, Messe Stuttgart (D)

23/02/27 - 26/02/27: Anuga FoodTec, Keulen

17/03/27 - 18/03/27: M+R, Antwerp Expo (B)

14/06/27 - 18/06/27: ACHEMA, Frankfurt am Main (D)

22/06/27 - 25/06/27: Automatica, München (D)